Flat Jacquard Knitting Machine

Made in China | NN0409-0674

- Code:YK 06

- Sale Price:Call

FLAT JACQUARD KNITTING MACHINE

- Model : DZ

- Gauge 14 - 16GG

- Needles/Maximum knitting width inch 80 inch

FUTURES

Transfer, jacquard, intarsia, pointel, truck, apparent shape, hidden shape and other regular pattern knitting functions...

SPECIFICATION

- Knitting system : Double carriage with single system

- Knitting speed (1) : Max knitting speed 1.7m/s. 32 speed sections controlled by servo motor.

- Stitch density : 32 density selection range 0-640 controlled by stepping motor, electrical fine adjust technology.

- Dynamic stitch : Controlled by stepping motor, 24 segment density selection, using subdivision technology, adjustable range:0-650, more accurate control of the length of the knitwear

- Rib transfer : Free transfer double ways between front and back needle at same time and no limitation by carriage movement. Transfer and knit individually.

- Single or double racking : Controlled by ac servo motor racking within 2 inches and with fine adjusting function

- SHAFT BAR : Servo motor and ball screw device are used to control the needle shifting range of 1-7 needles, and has precise fine-tuning function.

- Selector : 8 section of electronic needle selector in this Flat jacquard knitting machine.

- Yarn roller : Positive yarn roller precisely control the tension of the yarn to guarantee the fabric quality.

- Yarn carrier : The 2*8 yarn carriers are arrange on the left and the right sides of the 4 double side guide rails , can switch the position of the tip of the yarn in warp

- Automatic alarm : Machine auto stop when yarn break, yarn joint stuck, fabric roll inside ,needle hit, overload, program error and program end happens.

- Needle detector : Infrared sensor only detects the knitting area to avoid the miss alarming.

- Control system of Flat jacquard knitting machine :

- 1. Adopt LCD touch screen and figure interface, input device: USB internal storage 8G, a great amount of design files can be stored at the same time and they can be fetched out for use at any time as per production requirements.

- 2. Monitoring menu: each kind of operating parameter can be shown and can be adjust at any time when the machine is running, making conveniences for operations as much as upgrade.

- 3. Free design system is visual and easy to understand and upgrade.(Programing software comes from "HENGQIANG CNC" or Raynen)

- Data input : use USB and network to Flat jacquard knitting machine.

- Power off memory : Deviced advanced CMOS technology, the knitting data and file is saved for restart knitting once power off.

- The whole machine cover to reduce noise and dust, the protection cover is equipped with stopping sensor, emergency stopping, power off device

- POWER (2) : AC 220V- 50hz/6ohz ; Power: 1kw-1.5kw

- Depends on the gauge ,yarn and the pattern etc.

- The actual electricity consumption is far below the marked value ,depends on the gauge and the working condition.

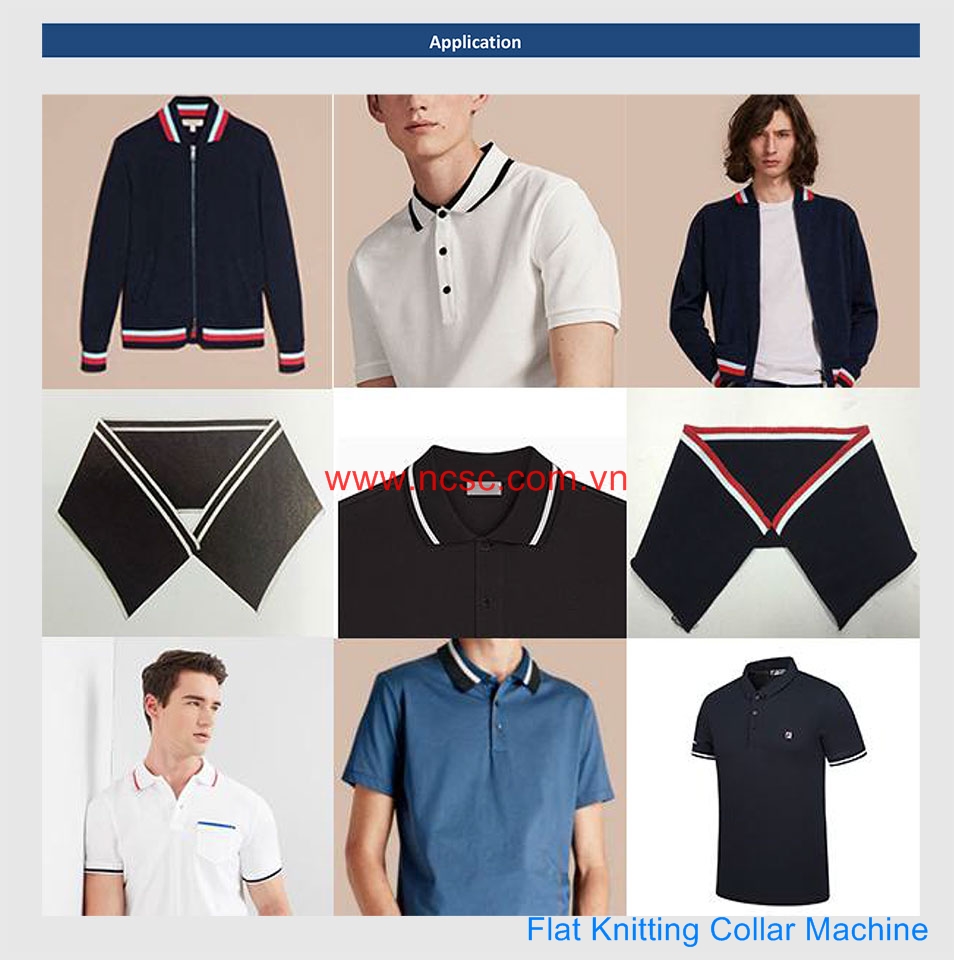

Some of other collar knitting machine

See more video, Please click here !

Relate Products

comment(s) (0)

Lastest News

Product List

Statistics

User Accessed 1,997,152

User Online10

Find us on ...

About us

NCSC Vietnam - operation in the fields of Commerce - Engineering & Services. Specialist suppliers of machinery, industrial equipment, textile (new machine & Used).

ThietbiDetNhuom.com - members of ncsc.com.vn page. A address information exchange, experience in manufacturing business of Weaving - Printing - Dyeing.

ncsc.com.vn

Information - Policy

Contact us

Add : 268/26 Nguyen thai Binh Rd., Bay Hien Ward, HCMC - VN

Hotline : (+84) 376 422 968

Email : thietbidetnhuom@gmail.com

Facebook.com/Cty TNHH NCS Viet nam

Copyright @ ncsc.vn

- Powered by IM Group

Send your comment