Singeing Machine

Made in China - Korea

Post date: 06-08-2016

10,079 view(s)

Singeing machine

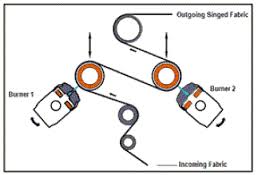

Singeing is using gas to heat of fire, heat or flame burned on the surface of the first fiber cloth, fiber cloth if there is no requirement to create fur, or create snow (sueding). Singeing be conducted mainly on fabric made from knitted or woven fibers.

The aim is to achieve the fabric surface without protruding fiber ends and soft, to facilitate the next technologies and use requirements.

Products Woven and knitwear made from the individual fiber types or mix can singeing. Singeing particularly important in cotton fabric finishing. Effective on the fabric surface reached after singeing will exhibit the properties of fabrics:

• Demonstrate clearly structured surface textile fabric

• Reduce dust during production & use next.

• The surface of the dyed fabric more stable by reducing the diffuse reflected light.

• Contributes to the sharpness of prints

• Support complete anti clotted fabric surface, especially with polyester or cotton / polyester

Factors affecting the combustion efficiency singeing machine:

The temperature of the fabric

Speed of cloth run

Burners

The rate stable peace between air & gas

...

Singeing machines currently produced in China or South Korea have been many significant improvements compared to the previous period: They were armed with axes chamber brush brush with different kinds. Fabric after carding can repair defects weaving, singeing increase efficiency. Equipped with inverter to adjust the speed of the machine; acquiring experience from the manufacturer renowned European gas bec (OSTHOFF - Germany); use of materials manufactured using high alloy bec; bec processing on CNC machines to increase accuracy; singeing machine design focuses on the use of savings, fuel diversity, comply with the handling of the smoke, dust discharged into the environment before ... fully meet the requirements of increasing production at VN.

See more, Please click here !!

Key : #dyeing machine #stenter machine #finishing machine #printing machine #other machine #weaving machine

Send your comment